A. Lange & Söhne Brand

German Silver – Aesthetically Appealing And Sophisticated

Luxferity, 15.12.2023

Introduced in 1864 by Ferdinand Adolph Lange, the three-quarter plate was incorporated in the historic pocket watches of the Glashütte manufacture. Since then, it has represented a prominent hallmark of A. Lange & Söhne timepieces. It was partially crafted from untreated German silver – an alloy introduced in Saxony in 1823. Since the re-establishment of the manufacture in 1990, plates, bridges and cocks have also been made of this material. But what are the distinguishing characteristics of this material and how did it come by its particular name?

The cases of the A. Lange & Söhne timepieces are crafted from different types of precious metal and, since 2019, also from steel. Yet on the inside, all watches have one common denominator: the frame is made of German silver. The frame includes, for example, the base plate, the three-quarter plate, the balance cock and the escape-wheel cock. It is an assortment of planar and supporting elements that are not directly involved in the transmission of force.

As early as the 1850s, Ferdinand Adolph Lange used German silver in individual pocket watches whose frame parts had, until then, habitually been made of upgraded brass or hardened steel. At that time, the alloy, consisting mainly of copper, zinc and nickel, had only recently been introduced, and featured the properties that Lange needed to confer the desired characteristics on its movements. As is the case with brass, German silver lends itself well for decoration, it is, however, a little harder and, in general, more resistant to tarnishing and corrosion. Thus, it can be used without prior gilding and gradually develops only a very light patina. In addition, German silver exhibits a greater wear resistance and resilience as well as rigidity.

Apart from the favourable material characteristics, it is highly probable that a further reason advocated its deployment: the sale of timepieces into the USA. Importing precious metals, in particular gold, was subject to high protective tariffs, necessitating the quest for alternative options for crafting the refined cases and movements made of gold-plated brass. These suppositions appear to be substantiated, as early Lange pocket watches were sold into the USA without a case. Additionally, the hitherto common gold-plated brass plates were suspected to be made of solid gold, since it was impossible to distinguish between gold-plated metals and solid precious metals. This would have represented too much of a hazard for the continued export. In those days, German silver also provided an alternative to real silver whose availability was steadily diminishing owing to the ongoing depletion of the mines in the Eastern Ore Mountains.

However, its true origins can be traced back to China: as early as the 17th century, metal goods made of the copper-zinc-nickel alloy “Packfong” were first shipped to Europe. Since importing the merchandise was cumbersome and costly, and, simultaneously, a robust material was needed to meet the constantly growing demand for cutlery, crockery and novel micromechanical parts, the first prerequisite was to “decipher” the components of the alloy – a feat that was finally accomplished in the 18th century.

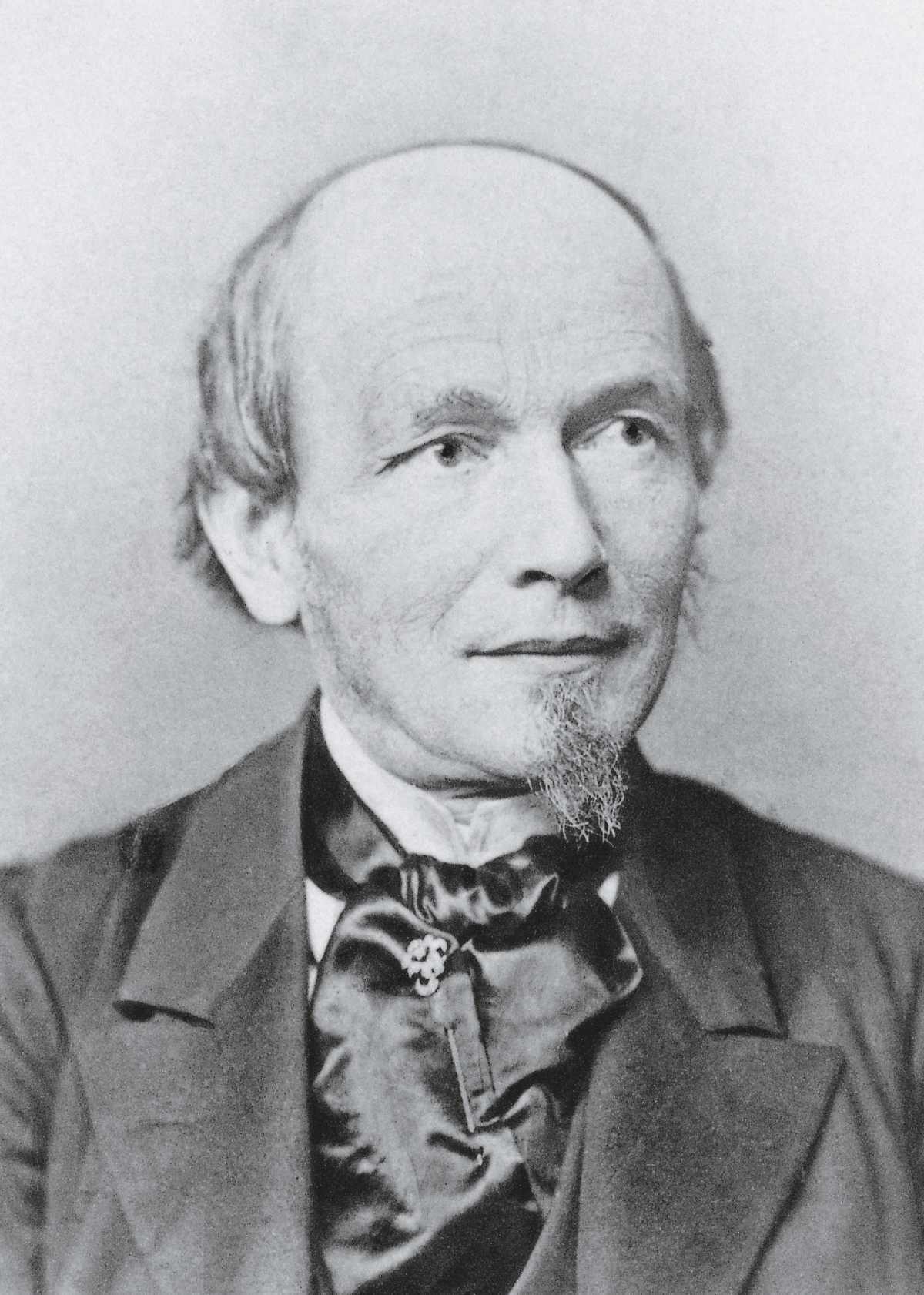

The quantum leap towards European, industrial production of German silver was marked by a competition instigated in 1823 by the “Association for the Promotion of Industriousness of Trade”: it targeted the invention of an alternative material that did not contain toxic compounds. The Saxon natural scientist and physician Ernst August Geitner (1783 – 1852), who studied in Leipzig and had been awarded a doctorate, established a small factory producing dyes for the textile industry in the Western Ore Mountains and won the competition. He developed a procedure for producing an alloy – very similar in appearance to silver – that became accepted thanks to its lustre and competitive price. In the first instance, Geitner named the metal mixture “argentan”, derived from the Latin “argentum” for silver. The name “alpacca” was also common, in particular for cutlery. In view of its history of origin, the material is nowadays known as German silver in English or “plata alemana” in Spanish.

The beneficial properties of German silver also strengthen its case today: its solidity is ideally suited for grinding, polishing or engraving surfaces by hand. The enhanced stability makes it predestined for frame parts, especially in movements of exceedingly complicated timepieces with diminutive margins for manoeuvre. The admixture of zinc, and particularly nickel, is responsible for its argentine appearance. The addition of nickel is conducive to the warm, subtle yellow-gold hue that the material assumes gradually, and also to the fact that it is not impaired by unattractive corrosions. Hence, German silver does not require a galvanic coating such as, for instance, gilding: it may remain untreated. And yet, the patina developed over time endows German silver with a distinctive attribute: it ages gracefully.

During the first assembly of the movement, even an experienced watchmaker has to mount and dismount the three-quarter plate several times, until every toothed wheel of the wheel train has the optimum endshake. Since immaculacy is a prerequisite, the watchmakers wear finger cots when handling the material. In view of the complexity involved in the assembly, and our high quality standards, A. Lange & Söhne watches are assembled twice with the utmost care.

The ensemble of components crafted from German silver and other, also meticulously finished movement parts creates an impressive stage setting. They include steel parts such as arbors, levers or springs, gold-plated toothed wheels as well as solid-gold chatons, red jewels and blued screws. Thanks to the transparent sapphire-crystal caseback, the orchestrated play of colours and aesthetics of the different materials can be admired at any given time.

Tino Bobe, Director Manufacture, explains: “German silver is part of all our manufacture calibres, amounting to more than 70 that have been developed and built since the re-establishment of A. Lange & Söhne. Hence, its consistent usage is typical of the Lange way of crafting watches. It underscores our commitment to never take the easiest path but always the one that leads us to the best result. For the benefit of quality, aesthetics, and functionality of our movements, we are prepared to invest the utmost artisanal effort – with a view to German silver but also far beyond.”