The Self-Powered Illumination Technology Trigalight: Always A Bright Light

Luxferity, 21.09.2021

The self-powered illumination technology trigalight brightens up any watch component for years and allows perfect readability at all times. With the smallest gaseous tritium light sources (GTLS) in the world, the Swiss microtechnology specialist mb-microtec ag offers a fascinating and unique luminant for the watch industry. trigalight thus turns every time piece into an outstanding eyecatcher – for a design that lasts whether during the day or late at night.

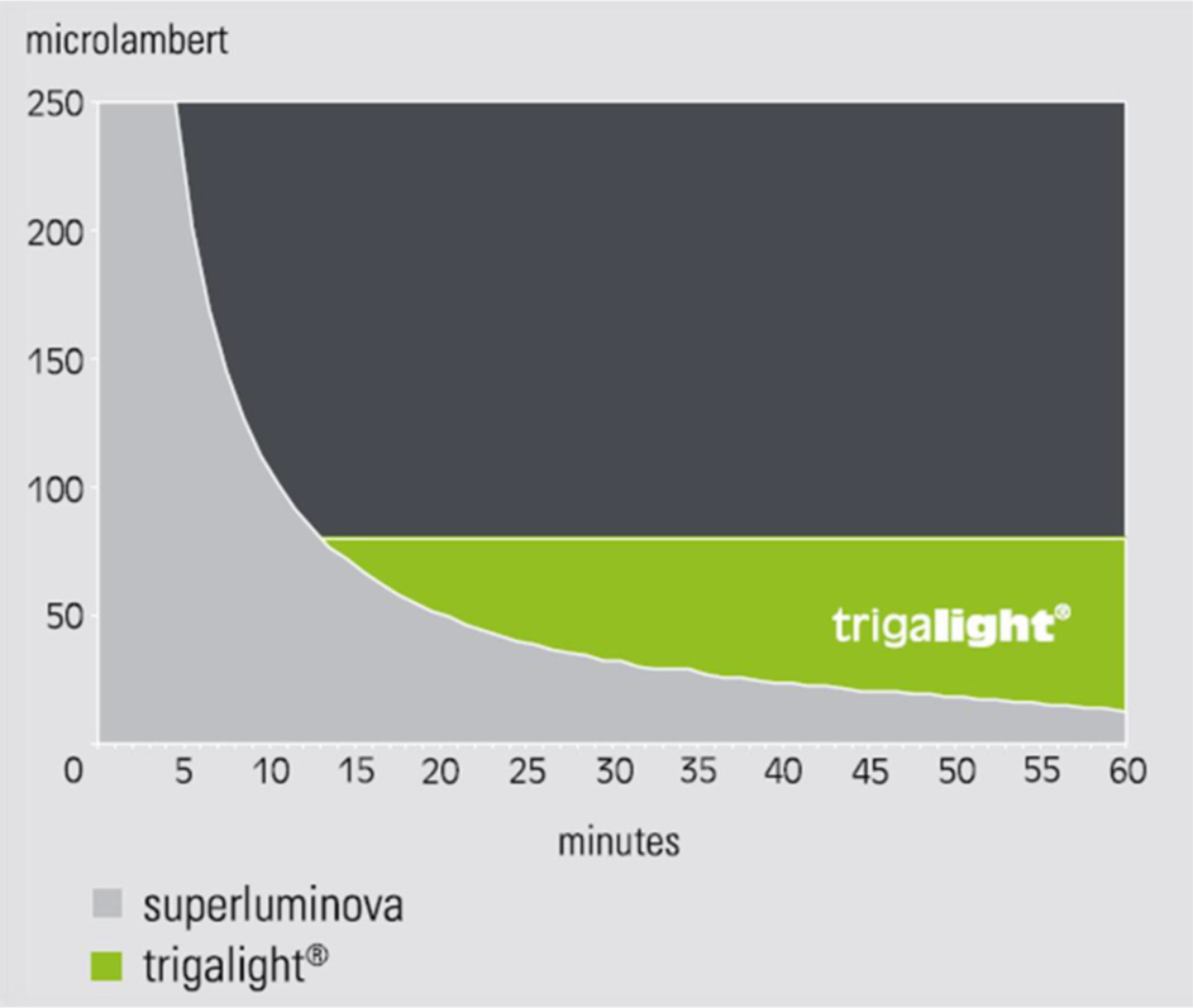

Sophisticated watch design combines precision, functionality, and aesthetics into a reliable, steady indication of time. Therefore, the use of various luminescent substances is meant to enable readability even at night. Aside from its functionality, the application of luminescent substances onto indices or hands also serves as a design element – which, however, fades away within a few hours for most common luminescent materials.

With trigalight, the inventor of the world’s smallest gaseous tritium light sources mb-microtec ag offers a luminescent substance for the watch industry standing out against all traditional materials by one determinant factor: A constant luminescent for years without any external source of power. In addition, the Swiss made illumination technology is absolutely safe, maintenance free, and can be integrated into any watch component thanks to its minimal installation size as well as a broad range of colors and shapes. Therefore, trigalight becomes a unique design element, brightly emphasizing functionality and form factor of watches.

Safety first. Design, too!

trigalight are fine, hermetically sealed glass capillaries, the inside of which is coated with the luminescent powder zinc sulfide and filled with tritium gas. During the decay of tritium, electrons are emitted, activating the luminescent powder, and thus creating long-lasting luminescence. Since tritium only has very low activity and electrons cannot pass through the hermetically sealed glass capillaries, trigalight does not emit any harmful radiation. Theoretically, a single piece of paper would suffice for complete radiation shielding. Beyond highest safety and quality standards, mb-microtec ag guarantees a constant luminescence of over 10 years. With that, trigalight distinguishes itself significantly from all common luminescent substances and ensures perfect readability of the watch at any time.

100 percent Swiss made. 100 percent unique.

Ever since its invention, the entire development and manufacturing process from a single source has taken place at the Swiss headquarters in Niederwangen close to Bern. The close connection of research and production enables mb-microtec ag to keep developing its technology further and adjusting it more and more to the customers’ needs.

“As a Swiss family business, we know the demands and aspirations of the watch industry well: Highest quality standards, Swiss made precision and innovative individuality. Exactly these values also define our trigalight products. Therefore, it is with our expertise that we stand by our clients’ side from the first idea, via production and all the way to regulatory issues as an advising partner and develop unique illumination solutions together with them,” describes Simone Gafner her work in the development division at mb-microtec ag.

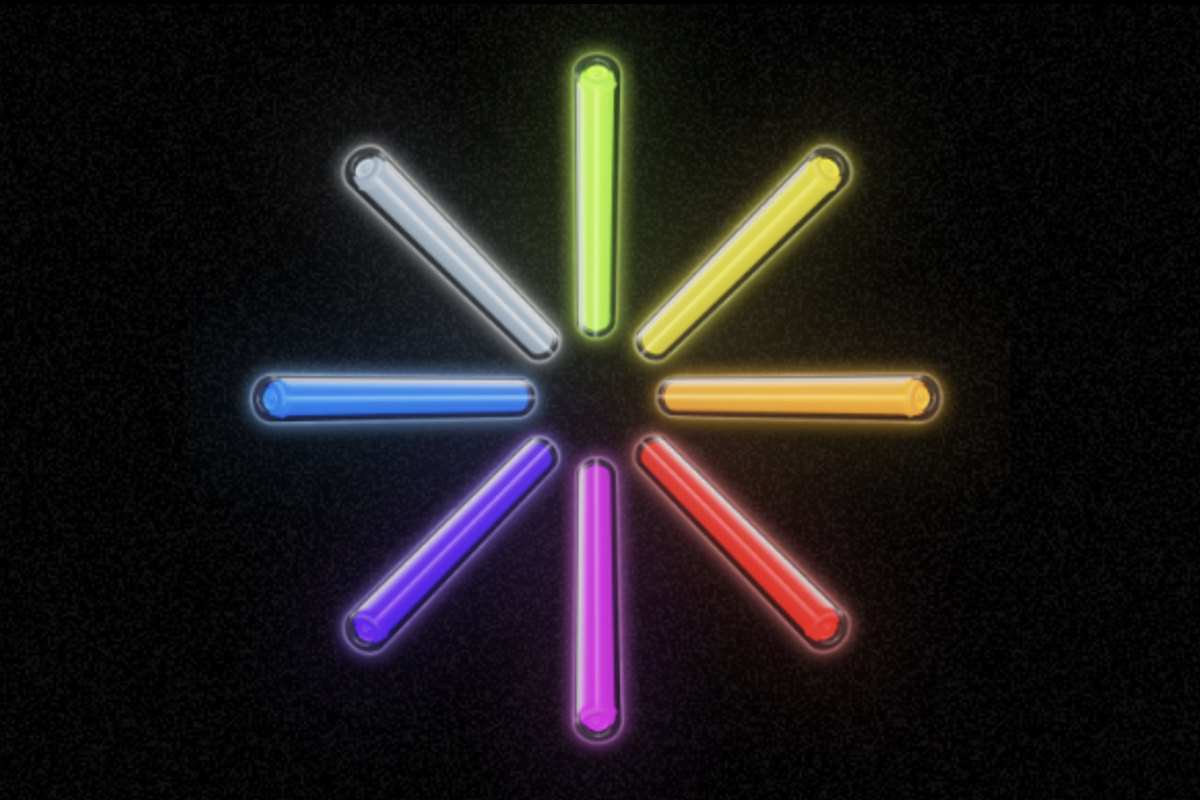

Great variety – minimal installation size

Aside from a broad range of standardized products, the Swiss microtechnology company also offers the development of customer specific solutions. Beyond the preferred color green, the color perceived brightest by the human eye, the capillaries are available in orange, yellow, white, ice blue, pink, purple, and blue as well as individualized color blends. Watch components such as bezels, hands and indices are usually equipped with so-called watch lights, the smallest types of trigalight. In their finest execution, their outer diameter measures as little as hair-thin 0.3 millimeters. These “hairlights” are the smallest gaseous tritium light sources (GTLS) in the world and can be applied onto particularly fine watch parts. While their standard cross-sectional shape is round, trigalight can also be manufactured with a square and rectangular form as well as with an adjustable length.

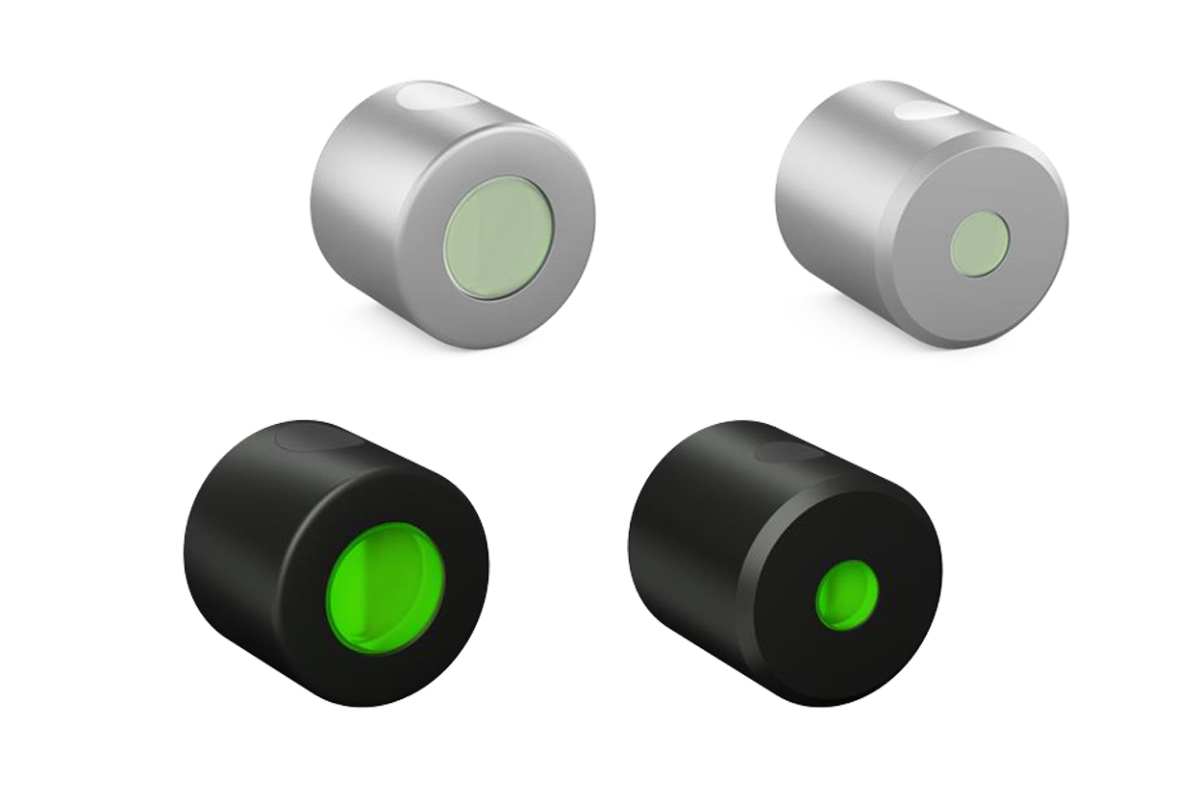

Integrated Products: Radial Insert and Helios ring

In addition to trigalight alone, mb-microtec ag offers its technology as integrated products. The Radial Insert, suitable for the illumination of a bezel for instance, coats a lengthwise placed trigalight with a protective sleeve, and appears as a round luminous dot after installation. The cover also allows for a quick direct assembly of the inserts.

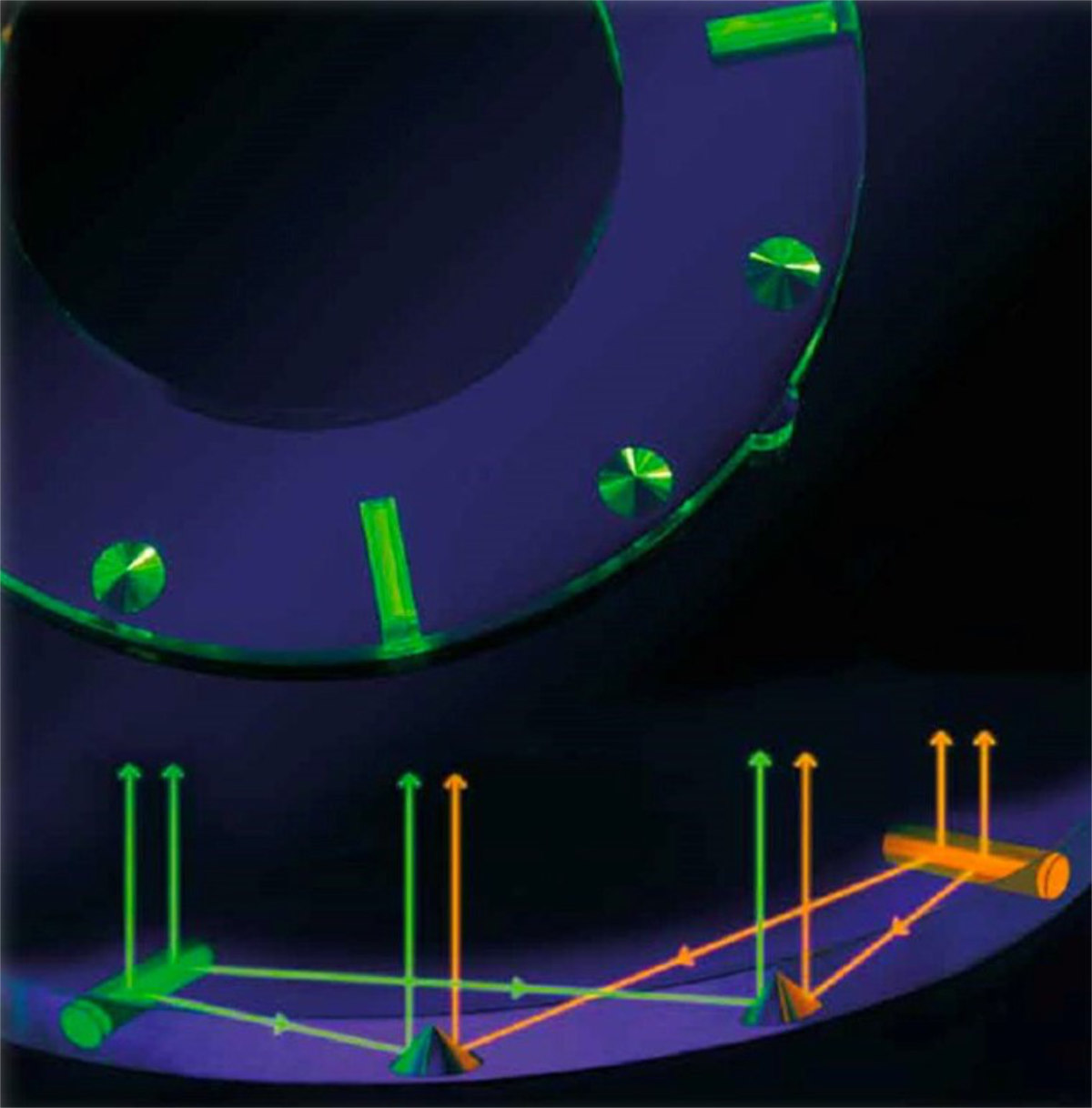

Even more opportunities lie in the combination of trigalight with further illumination technologies. The product concept “Helios” – ancient Greek for “sun” – utilizes an optical fiber to precisely spread the light generated by a trigalight capillary. By placing the Helios ring underneath the dial, selected areas such as the indices can be lit up.

In general, the compatibility of trigalight offers a multitude of possibilities to make watches shine in a very special light – whether in absolute darkness or in case of poor visibility. With that, the technology can easily be combined with any common luminous substances and parts and integrated together with these into a unique watch design.

Greatly customizable, exceptionally functional and 100 percent Swiss made: The self-powered illumination technology trigalight lends every timepiece constant readability and a design that attracts attention at all times.

About trigalight self-powered illumination

trigalight is a brand of mb-microtec, a microtechnology company founded in 1969 in Niederwangen near Bern. The brand represents a unique self-powered illumination technology with the world’s smallest gaseous tritium light sources (GTLS) that deliver luminescence for decades without any external energy source.

mb-microtec ag is the inventor and global market leader in the development and production of this unique self-powered illumination technology, that is primarily used in the tactical, watch, security, automotive, aerospace, and aeronautical industry. Around one hundred qualified employees work at the Swiss headquarters of the family-owned company, which has comprehensive knowledge in the fields of microtechnology, chemistry and physics as well as a state-of-the-art infrastructure where the entire development and production processes take place. Up to 90 percent of the Swiss made goods are exported.